Technology

Engineered for global adaptability.

We’ve spent over 25 years refining our fast pyrolysis technology for cleaner, more sustainable energy solutions. Converting biomass into BioOil, BioChar, and non-condensable gases provides an efficient, scalable process that reduces carbon emissions, creates renewable energy, and fosters local economic growth.

Our technology is capable of processing over 140 types of biomass feedstocks to meet the sustainability needs of diverse industries and regions, from replacing fossil fuels and sequestering carbon to restoring degraded land.

What is fast pyrolysis?

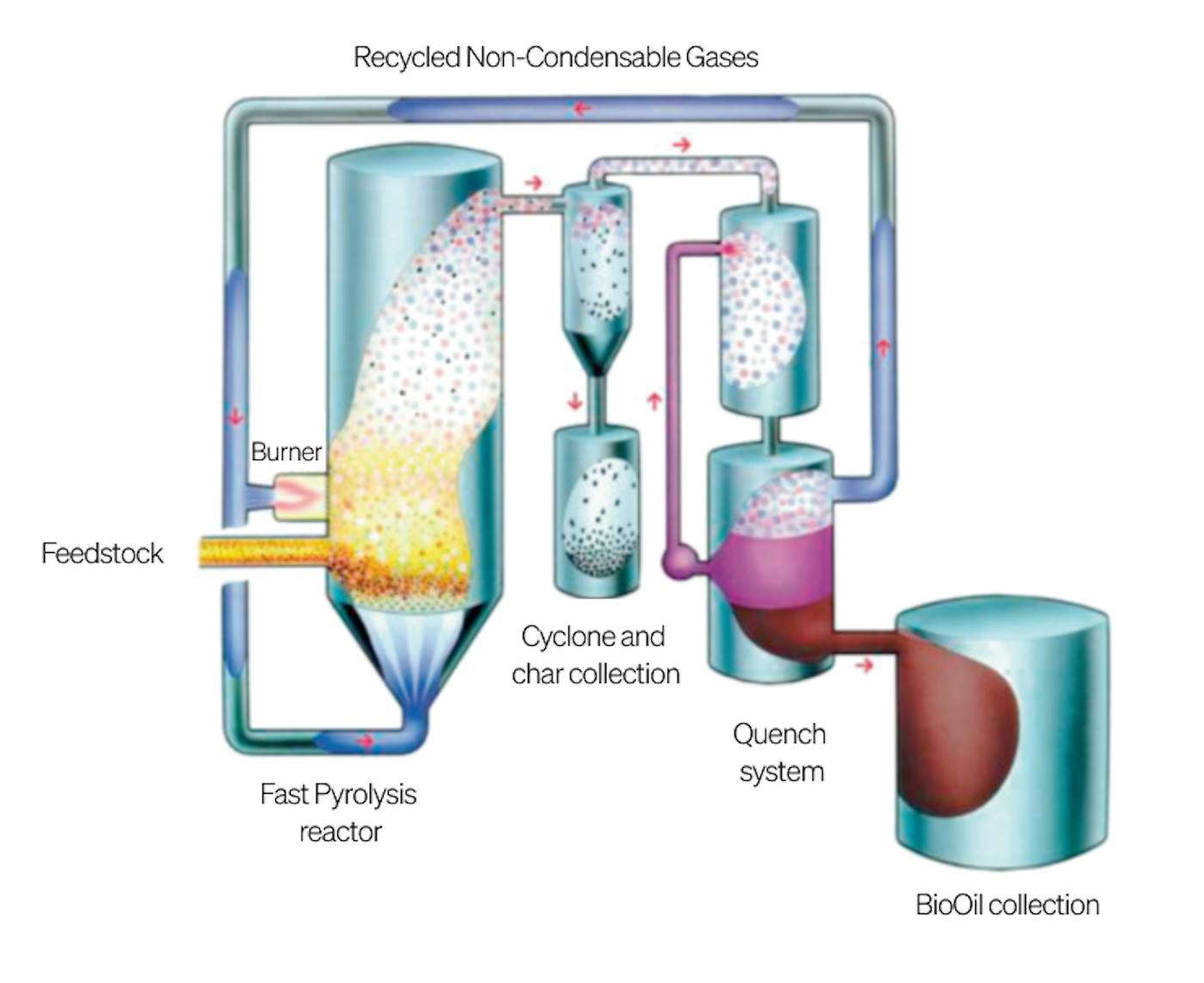

Fast pyrolysis is a thermochemical process that rapidly heats biomass (e.g., organic matter from plants) in the absence of oxygen to produce liquid BioOil, solid BioChar, and non-condensable gases.

Highlights of fast pyrolysis include low emissions products, high efficiency, and cost-effective operational costs. Plants can be set up quickly anywhere there is biomass feedstock available.

The pyrolysis process happens at high temperatures (400-600°C) over the span of less than two seconds. This rapid heating prevents the complete combustion of the biomass, favoring the formation of liquid BioOil. The process parameters can be adjusted to favor the production of BioOil or BioChar.

How it works

Biomass input

Agricultural residues, forestry waste, and other biomass feedstocks are collected and prepped for processing.

Rapid heating

The biomass is rapidly heated to 400–600°C in the absence of oxygen, preventing combustion and breaking down its molecular structure.

Product separation

The vaporized biomass is cooled and condensed into liquid BioOil, while solid carbon-rich material is separated out as BioChar.

Recycle gases

The process also produces non-condensable gases which are recycled within the system to provide the heat needed for the pyrolysis process.

Why fast pyrolysis?

Rapid biomass conversion

Biomass is heated to 400–600°C in under two seconds, transforming it into BioOil, BioChar, and non-condensible gases with exceptional efficiency.

Modular and scalable design

Our plants are modularly designed for rapid deployment across the globe, enabling scalability and minimizing capital risks.

Low-emission process

The process produces no SOx and very low NOx emissions, contributing to cleaner air and reduced environmental impact.

Flexible feedstock use

From agricultural residues like sugarcane bagasse to forestry by-products, our technology processes over 140 biomass types with ease.

Energy efficiency

Non-condensable gases generated during pyrolysis are recycled to power the process, minimizing external energy needs.

Technology benefits

By converting underutilized biomass into renewable BioOil and BioChar, we enable industries, governments, and communities to reduce their carbon footprint, create new revenue streams, and foster sustainable development.

Each plant reduces CO₂ emissions by up to 800,000 tons annually and converts underutilized biomass into valuable products, preventing environmental degradation and waste accumulation.

Each plant creates 20–30 direct jobs and stimulates regional supply chains. The products themselves replace costly fossil fuels, saving industries millions annually (BioOil) and enable participation in carbon credit markets, generating additional income (BioChar).

Our technology works anywhere biomass is available, with plants already operational in diverse environments using a variety of feedstocks. Our R&D pipeline is focused on expanding BioOil applications to marine bunkers, sustainable aviation fuels, and transport fuels.

Modern bioenergy use more than doubles by 2050, due to its ability to be used as a direct drop-in substitute for fossil fuels.